- Identifying And Marking the Line Number of each Piping System, Instrument, and structure Using Available P&ID And Structural Drawings to Input Details into the Software while Matching Marking.

- Identifying And Marking Split Points onto Piping & Structure, Keeping in mind Rigging & Logistics (40ft Container) Feasibility Only.

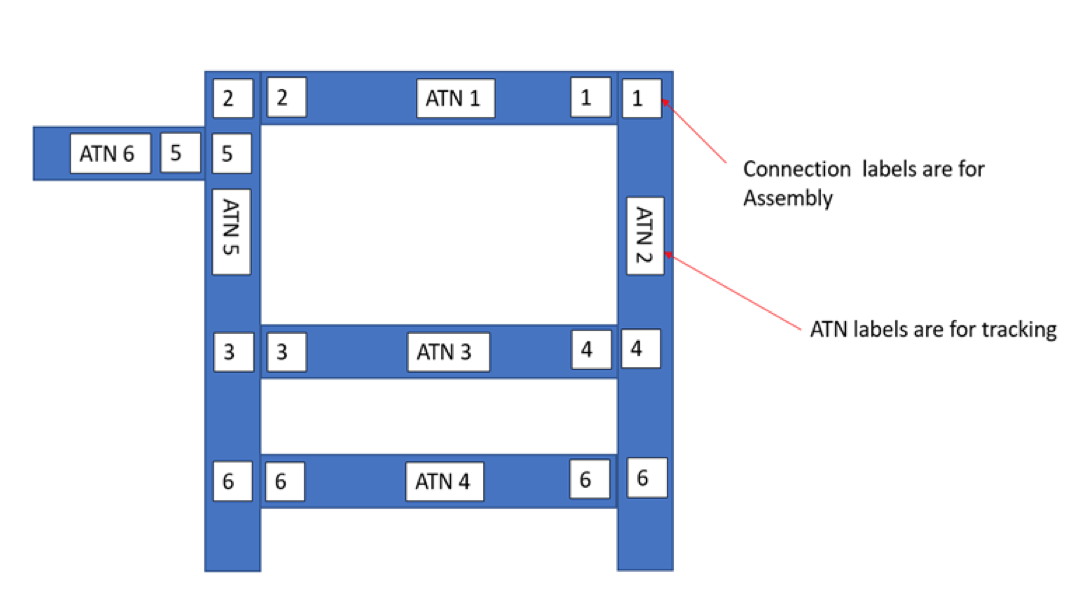

- Marking Spools on either Side of the Split Point with two cut-Label QR codes (Either End of Spool) for connecting the Joining Location and 1 Asset Tag Number (ATN) QR Code at The Centre for Tracking the Asset. Both Codes Are Issued by The Software Having a Unique Number and Are Done at the Start of the Workday

CUT LABEL

ATN LABEL

CUT LABEL

A Cut Label to Store Information Regarding the kind of Cut, i.e.

- Bolted

- Hot Cut

- Cold Cut

- Flanged

- Size

An ATN to store information regarding the Asset

- Type

- Location

This Helps to Track the Items from the Donor Site Right Up to the Build Site.

- Once QR codes are pasted onto the spools they are linked with adjacent cut codes using software pre-installed on Tabs and a single tick is made next to the ATN code. Labels are positioned safely, to allow the cut to be made at a safe distance to prevent heat or other damage from the cutting process.

- QR codes are pasted onto spools and coated with epoxy resin with hardener to get a laminate finish thereby ensuring the codes are protected.

- At the end of day all codes scanned at field on respective tabs are synced onto central server via the software for review and updating and another tick is made next to the ATN code the next day signalling the spool is ready to dismantle.