/Ammonia1.png)

Ammonia I (1000 MTPD)

The ammonia production plant, commissioned in 1984 with a capacity of 1000 MTPD, operates under the guidance of Haldor Topsoe as the process licensor. Its core features include, Steam System having a total capacity of 330 Tons/Hr consists of a Franco Tosi Boiler (130 tons per hour), and Waste Heat Boiler with Steam Super Heater (200 Tons/Hr), Ammonia Converter equipped with S-300 Baskets, Primary Reformer by Technipetrol-Nova s.p.a integrated with catalyst tubes, turbine-driven compressors by Nuovo Pignone for natural gas, process air, synthesis gas, and ammonia needs. Other major equipment includes Absorbers, Regenerators, Secondary Reformer, Converter, Separators, Condensers & Heat Exchangers.

| PROCESS LICENSOR | Haldor Topsoe |

|---|---|

| PRODUCTION CAPACITY | 1000 MTPD |

| YEAR OF COMMISSIONING | Commissioned in 1984 with a Production Capacity of 1000 MTPD |

| STEAM CAPACITY | Franco Tosi Boiler (130 Tons per Hour Capacity). Waste Heat Boiler with Super Heater- 200 T/Hr. |

| KEY FEATURES AND EQUIPMENTS | Ammonia Converter with S-300 Baskets |

| Turbine-driven compressors (Nuovo Pignone) for Natural Gas, Process Air, Synthesis Gas, and Ammonia Compressors. | |

| Primary Reformer by Technipetrol- Nova s.p.a | |

| Secondary reformer by ATB Brescia | |

| H.P.C absorber and regenerator by Hyundai heavy industries | |

| M.E.A absorber and regenerator Hyundai heavy industries | |

| Hydrogenator by ATB Brescia | |

| H2S Absorbers ATB Brescia | |

| H.T./L.T Shift Converter by ATB Brescia | |

| Methanator by ATB Brescia | |

| Natural Gas Preheater by Heurtey petrochem | |

| Ammonia Separator by Nuovo Pignone | |

| Ammonia Condenser by Novo Pignone | |

| And all related static and rotary equipment, such as Vessels, drums, columns, heat exchangers, pumps, etc. | |

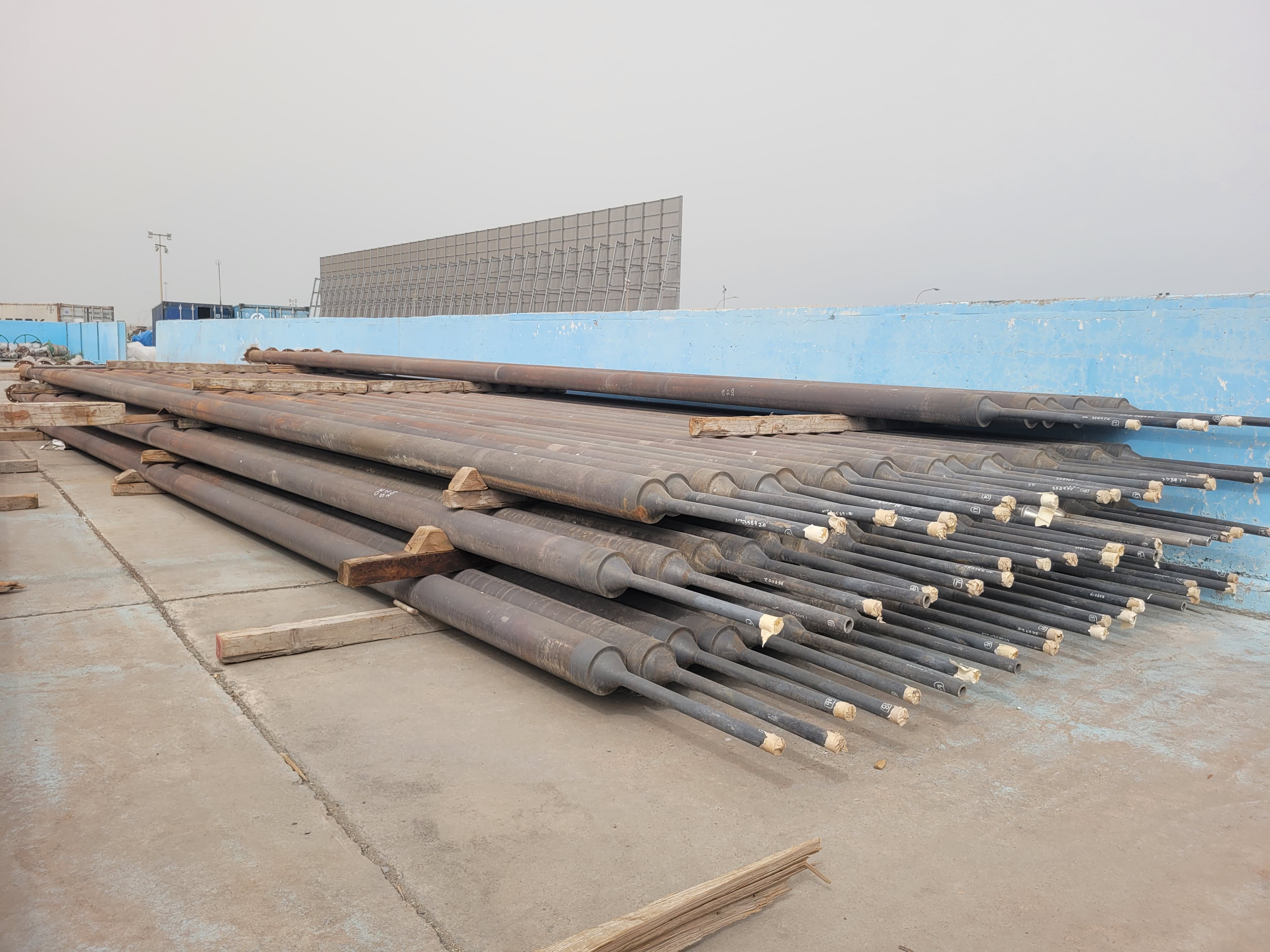

| CURRENT STATUS | The unit has been dismantled after 3D Scanning and Match Marking with QR Codes for asset tracking. All the assets were preserved per the applicable Preservation Procedure. |

/Amm.IV Gas Pre Treatment Plant - West Side 2.jpg)

/Amm.IV Gas Pre Treatment Plant South Side 2.jpg)

/Amm.IV Gas Pre Treatment Plant West Side.jpg)

/Amm.IV Gas Treatment Plant East Side.jpg)

/Amm.IV MEA Gas Pre Treatment Plant South Side.jpg)

/Amm.IV Reformer Area East Side 2.jpg)

/Amm.IV Reformer Area East Side.jpg)

/Amm.IV Synthesis Area 1.jpg)

/Amm.IV Synthesis Area 2.jpg)

/Amm.IV Synthesis Area 3.jpg)